How does a test valve work. Non-return or one-way valves, typically known as test valves, are important components of liquid programs that assure a regulated and unidirectional circulate of fluids. These valves are important for stopping backflow, preserving system performance, and defending {hardware}. They’re utilized in a wide range of industries, together with oil and fuel, water and wastewater therapy, and extra. This in depth essay will discover the kinds, makes use of, and choice standards for test valves in addition to how they function.

How does a test valve work

Definition and Goal

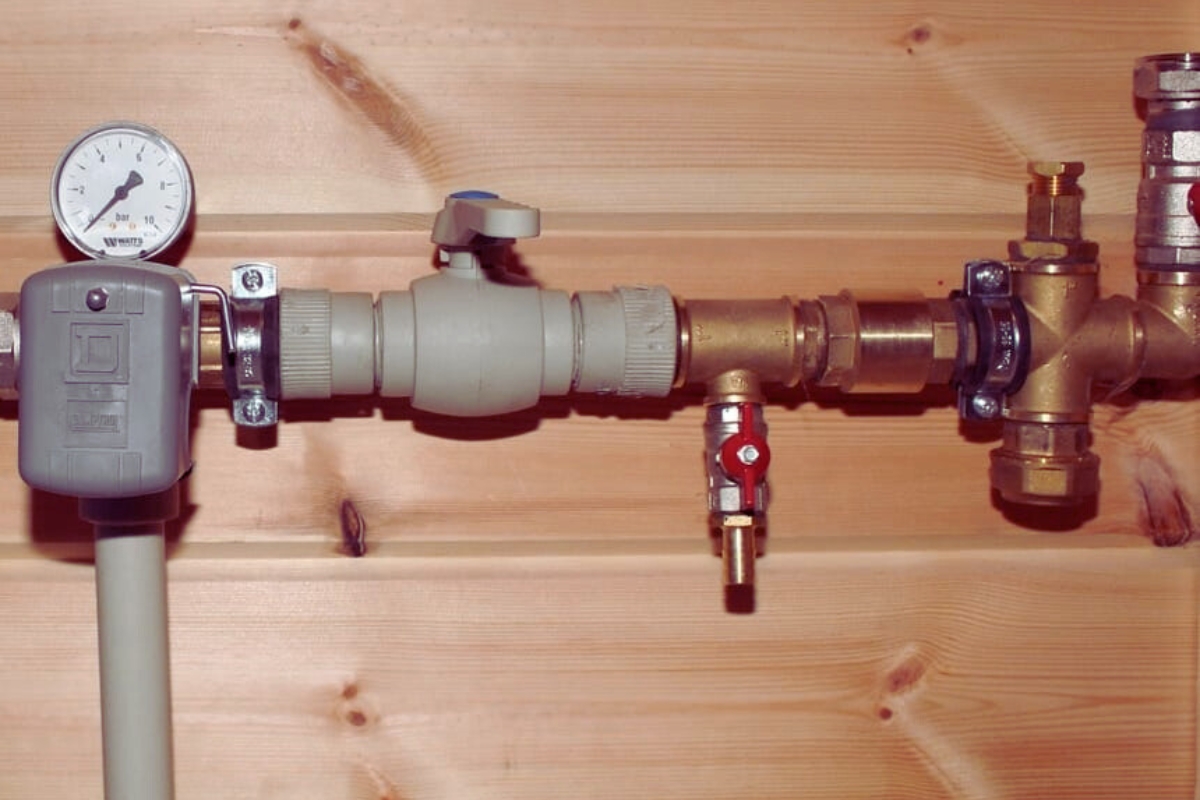

A test valve could also be a mechanical gadget designed to permit fluid circulate in a single course whereas stopping backflow within the different. The first goal of a test valve is to make sure that a fluid, whether or not liquid or fuel, can transfer by means of a system unrestricted within the anticipated course, however any try at inverting circulate is instantly blocked.

Kinds of Examine Valves

- Swing Examine Valve:

- Makes use of a hinged circle to allow a stream in a single course and squares it within the inverse course.

- Generally utilized in functions with usually low-pressure programs.

- Elevate Examine Valve:

- Employs a guided disc that lifts off its seat to allow a ahead stream and closes beneath the affect of reverse circulate.

- Appropriate for high-pressure programs.

- Ball Examine Valve:

- It consists of a spherical ball that strikes in response to liquid circulate, permitting or blocking the part.

- Recognized for its speedy response time and low repairs necessities,

- Diaphragm Examine Valve:

- It makes use of a versatile diaphragm to regulate the stream course, making it applicable for functions with grating or corrosive fluids.

- Inline Examine Valve:

- A compact valve design that matches immediately right into a pipeline, permitting for easy set up and upkeep.

How Examine Valves Work

Working Precept

The elemental operation of a test valve depends on the liquid strain and the mechanical design of the valve. When the liquid flows within the desired course, it makes a drive that opens the valve, permitting the liquid to cross. Nevertheless, when there’s an try at turn-around circulate, the valve promptly closes underneath the influence of gravity, spring stress, or the strain of the backflow.

Gravity-Operated Examine Valves

In gravity-operated test valves, the burden of the valve plate or ball ensures closure when the stream stops. These valves are generally utilized in vertical pipe installations the place gravity helps with the closing mechanism.

Spring-Loaded Examine Valves

Spring-loaded test valves incorporate a spring mechanism that helps shut the valve quickly when the circulate course modifications. This kind is appropriate for each vertical and horizontal installations and is regularly utilized in functions with various circulate charges.

Functions of Examine Valves

Examine valves discover utility in numerous industries, every with distinctive necessities:

- Water and Wastewater Therapy: Stopping backflow in pump programs and maintaining strain in pipelines.

- Oil and Fuel: Safeguard pumps and compressors from invert streams to anticipate injury.

- HVAC Techniques: Controlling the circulate of refrigerants and guaranteeing system effectivity.

- Manufacturing and Processing: Regulating liquid circulate in chemical dealing with and manufacturing crops.

- Energy Era: Defending generators and avoiding backflow in cooling programs.

Components Influencing Examine Valve Choice

- Circulation Fee and Strain: The design and kind of test valve should match the stream fee and weight necessities of the system.

- Materials Compatibility: Examine valves are accessible in numerous supplies, and the selection is dependent upon the kind of liquid being handed on and the environmental situations.

- Set up Orientation: Some test valves are extra appropriate for vertical installations, whereas others work effectively in degree orientations.

- Upkeep Concerns: The benefit of upkeep and the frequency of required inspections influence the selection of test valve kind.

Conclusion

Examine valves are indispensable parts in liquid programs, making certain the managed and efficient growth of liquids whereas stopping undesirable backflow. Their differing designs and functions make them very important for the graceful operation of various industries, emphasizing the significance of choosing the right kind of test valve for specific system necessities. Understanding the mechanics, types, functions, and influencing parts permits engineers and system designers to create knowledgeable selections, finally contributing to the reliability and longevity of liquid programs throughout numerous sectors.

Trending Merchandise